The 3 stages of quenching are the Vapor Stage, the Boiling Stage, and finally the Convection stage. These stages are in reference to the interaction between the quenchant and the component being cooled. Vapor Stage: In this stage the super-heated component immediately vaporizes the quenchant. The gaRead more

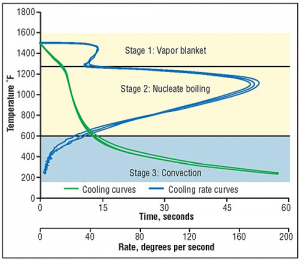

The 3 stages of quenching are the Vapor Stage, the Boiling Stage, and finally the Convection stage. These stages are in reference to the interaction between the quenchant and the component being cooled. Vapor Stage: In this stage the super-heated component immediately vaporizes the quenchant. The gaseous quenchant now surrounds the component in a thin sheet, and the liquid quenchant is no longer in contact with the component and the heat therefore slowly seeps out of the component by radiation and limited conduction. Boiling Stage: As the vapor insulation degrades and collapses, the component begins to boil the quenchant. Due to the direct contact with the liquid quenchant, cooling occurs quicker than the vapor stage. Eventually, as the heat diffuses into the liquid, the interface temperature drops below boiling and the convection stage begins. This is a similar principle to that which allows this to occur (see video). This is called the Leidenfrost Effect (https://en.wikipedia.org/wiki/Leidenfrost_effect#:~:text=The%20Leidenfrost%20effect%20is%20a,the%20liquid%20from%20boiling%20rapidly.) Convection Stage: Finally, the convection stage occurs after boiling has ceased and the heat can only be transferred by convection. The rate of cooling gradually decays as the system approaches equilibrium. Please see the graphical illustration below.  Image courtesy of Globalspec.com

Image courtesy of Globalspec.com

References: Understanding the Cooling Curve Test by D. Scott MacKenzie courtesy of Thermal Processing Magazine https://www.houghtonintl.com/sites/default/files/resources/article_-_understanding_the_cooling_curve_test_0.pdf

See less

Bottom-loading vacuum furnaces offer several advantages over other types of vacuum furnaces, such as top-loading or front-loading furnaces. These advantages make them particularly well-suited for specific applications in aerospace, automotive, and other high-tech industries. Here are some of the keyRead more

Bottom-loading vacuum furnaces offer several advantages over other types of vacuum furnaces, such as top-loading or front-loading furnaces. These advantages make them particularly well-suited for specific applications in aerospace, automotive, and other high-tech industries.

Here are some of the key advantages of bottom-loading vacuum furnaces:

1. Easy Loading and Unloading:

Bottom-loading furnaces are designed with a hinged or tilting door at the bottom of the chamber for easy loading and unloading of heavy or delicate workpieces. The materials can be placed on a platform or a tray that is lowered into the furnace chamber from the bottom. This eliminates the need for complex mechanical handling systems, making the loading and unloading process more efficient and thus reducing the risk of damage to the parts.

2. Enhanced Safety:

Bottom-loading vacuum furnaces provide enhanced safety for operators. Since the hot zone is located at the bottom, this reduces the potential for workplace accidents and ensures the safety of the operators. Additionally, the door design typically ensures a tight seal, minimizing the risk of vacuum leaks.

3. Energy Efficiency:

Since the heating elements and insulation are located at the top of the chamber, heat is less likely to escape during operation, which can result in lower energy consumption and faster heating and cooling cycles.

4. Better Temperature Uniformity:

Bottom-loading furnaces can provide more uniform temperature distribution within the chamber, as the heating elements are positioned at the top. This ensures consistent heat treatment across the entire workpiece, resulting in improved product quality and uniform properties.

5. Versatility & Flexibility:

Bottom-loading vacuum furnaces can accommodate a wide range of material sizes and shapes or irregularly shaped materials that may not be suitable for other types of furnaces. Their versatility makes bottom-loading furnaces suitable for a wide range of heat treatment processes and applications across different industries.

6. Improved Accessibility:

Bottom-loading furnaces provide better access to the furnace chamber, allowing for easier maintenance, cleaning, and part manipulation. This accessibility can lead to reduced downtime for maintenance and repairs.

7. Enhanced Cooling Options:

Many bottom-loading vacuum furnaces offer flexible cooling options, such as gas quenching or liquid cooling, which can be tailored to specific heat treatment processes. This capability allows for precise control over cooling rates and the achievement of desired material properties.

8. Improved Heat Distribution:

The bottom-loading design of the furnace chamber allows for improved heat distribution during the heating and cooling cycles. The heating elements are typically located at the top, bottom, and sides of the chamber, ensuring uniform heating of the materials. This results in better temperature control and more consistent heat treatment processes.

9. Reduced Footprint:

Bottom-loading furnaces often have a more compact footprint compared to top-loading or front-loading models, making them suitable for facilities with limited space.

10. Reduced Contamination:

Bottom-loading furnaces minimize the risk of contamination during the loading and unloading process. The materials being processed are not exposed to the overhead environment, which may contain airborne contaminants. This helps maintain the purity and quality of the processed materials, especially in applications where cleanliness is critical, such as in semiconductor manufacturing or aerospace industries.

While bottom-loading vacuum furnaces have numerous advantages, it is important to note that the advantages of a bottom-loading vacuum furnace may vary depending on the specific design and features of the furnace. Therefore, it’s essential to choose the right type of furnace for your specific application and requirements. Factors such as the size and shape of your workpieces, desired temperature range, and process control features should all be considered when selecting the most appropriate vacuum furnace design.

It is also recommended to consult with manufacturers or experts in vacuum furnace technology to determine the most suitable type of furnace for your specific application.

What are the leading Batch Vacuum Furnace Manufacturers (OEMs) worldwide?

See less