Gas quenching in vacuum materials processing typically involves three main stages: Initial Quench or Rapid Cooling Stage The initial stage begins as soon as the heating cycle completes, and quenching gas (usually nitrogen or argon) is introduced into the vacuum chamber at high speed. The purpose ofRead more

Gas quenching in vacuum materials processing typically involves three main stages:

- Initial Quench or Rapid Cooling Stage

- The initial stage begins as soon as the heating cycle completes, and quenching gas (usually nitrogen or argon) is introduced into the vacuum chamber at high speed.

- The purpose of this stage is to rapidly reduce the temperature of the load from its peak processing temperature down to a temperature range where transformation to a desired microstructure begins (for example, the martensitic transformation in steel).

- This stage usually has the highest cooling rate due to the temperature difference between the load and quenching gas, as well as the high gas velocity.

- Transition or Intermediate Cooling Stage

- As the temperature differential between the load and the quenching gas decreases, the cooling rate naturally slows down.

- The system may adjust the gas flow rate, pressure, or fan speed to manage heat extraction effectively without causing stress or distortion in the parts.

- This stage ensures that the cooling continues at a controlled rate to maintain uniformity across the load and avoid thermal gradients that can lead to cracking or warping.

- Final or Slow Cooling Stage

- In the final stage, the cooling process slows further as the load approaches room temperature or the final desired temperature.

- The goal here is to gradually bring the load down to ambient temperature, especially in large or thick parts, to reduce any residual stress or avoid transformation that could cause dimensional changes.

- At this point, the quench gas flow may be significantly reduced or shut off as the load achieves thermal equilibrium with the chamber environment.

Each of these stages is crucial for achieving the required mechanical properties, microstructure, and dimensional stability of the processed parts, especially in materials like tool steels and high-speed steels that you handle. The ability to control these stages precisely allows for optimization of cooling rates for different materials and part geometries.

See less

The 3 stages of quenching are the Vapor Stage, the Boiling Stage, and finally the Convection stage. These stages are in reference to the interaction between the quenchant and the component being cooled. Vapor Stage: In this stage the super-heated component immediately vaporizes the quenchant. The gaRead more

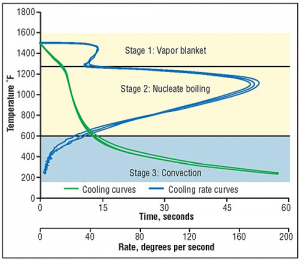

The 3 stages of quenching are the Vapor Stage, the Boiling Stage, and finally the Convection stage. These stages are in reference to the interaction between the quenchant and the component being cooled. Vapor Stage: In this stage the super-heated component immediately vaporizes the quenchant. The gaseous quenchant now surrounds the component in a thin sheet, and the liquid quenchant is no longer in contact with the component and the heat therefore slowly seeps out of the component by radiation and limited conduction. Boiling Stage: As the vapor insulation degrades and collapses, the component begins to boil the quenchant. Due to the direct contact with the liquid quenchant, cooling occurs quicker than the vapor stage. Eventually, as the heat diffuses into the liquid, the interface temperature drops below boiling and the convection stage begins. This is a similar principle to that which allows this to occur (see video). This is called the Leidenfrost Effect (https://en.wikipedia.org/wiki/Leidenfrost_effect#:~:text=The%20Leidenfrost%20effect%20is%20a,the%20liquid%20from%20boiling%20rapidly.) Convection Stage: Finally, the convection stage occurs after boiling has ceased and the heat can only be transferred by convection. The rate of cooling gradually decays as the system approaches equilibrium. Please see the graphical illustration below. Image courtesy of Globalspec.com

Image courtesy of Globalspec.com

References: Understanding the Cooling Curve Test by D. Scott MacKenzie courtesy of Thermal Processing Magazine https://www.houghtonintl.com/sites/default/files/resources/article_-_understanding_the_cooling_curve_test_0.pdf

See less