Ask | Share | Grow™ - Question & Answer Community

Of the Members, By the Members, For the Members!

VacuumFurnaces.com is a Q&A community where vacuum furnace product and service suppliers connect with commercial and captive heat treaters to share their practical skills and know-how and to establish valuable relationships around niche topics of expertise with vacuum furnace end-users in operations, production, training, maintenance, marketing, sales, and engineering.

What are the 3 stages of quenching?

The 3 stages of quenching are the Vapor Stage, the Boiling Stage, and finally the Convection stage. These stages are in reference to the interaction between the quenchant and the component being cooled. Vapor Stage: In this stage the super-heated component immediately vaporizes the quenchant. The gaRead more

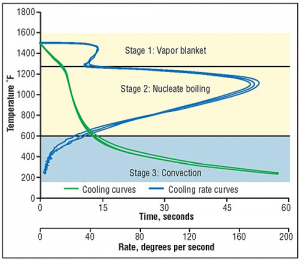

The 3 stages of quenching are the Vapor Stage, the Boiling Stage, and finally the Convection stage. These stages are in reference to the interaction between the quenchant and the component being cooled. Vapor Stage: In this stage the super-heated component immediately vaporizes the quenchant. The gaseous quenchant now surrounds the component in a thin sheet, and the liquid quenchant is no longer in contact with the component and the heat therefore slowly seeps out of the component by radiation and limited conduction. Boiling Stage: As the vapor insulation degrades and collapses, the component begins to boil the quenchant. Due to the direct contact with the liquid quenchant, cooling occurs quicker than the vapor stage. Eventually, as the heat diffuses into the liquid, the interface temperature drops below boiling and the convection stage begins. This is a similar principle to that which allows this to occur (see video). This is called the Leidenfrost Effect (https://en.wikipedia.org/wiki/Leidenfrost_effect#:~:text=The%20Leidenfrost%20effect%20is%20a,the%20liquid%20from%20boiling%20rapidly.) Convection Stage: Finally, the convection stage occurs after boiling has ceased and the heat can only be transferred by convection. The rate of cooling gradually decays as the system approaches equilibrium. Please see the graphical illustration below. Image courtesy of Globalspec.com

Image courtesy of Globalspec.com

References: Understanding the Cooling Curve Test by D. Scott MacKenzie courtesy of Thermal Processing Magazine https://www.houghtonintl.com/sites/default/files/resources/article_-_understanding_the_cooling_curve_test_0.pdf

See less

Why is carburizing less expensive than nitriding?

While both procedures have the same end goal of surface hardening components, nitriding and carburizing employ different resources and methods to do so, with different results. Carburizing is a heat treat process that uses carbon, while Nitriding uses nitrogen. Generally, each process diffuses the cRead more

While both procedures have the same end goal of surface hardening components, nitriding and carburizing employ different resources and methods to do so, with different results. Carburizing is a heat treat process that uses carbon, while Nitriding uses nitrogen. Generally, each process diffuses the chosen element into the surface of the component to produce a more wear resistant or harder surface. Nitriding is a better process for precision components, whereas carburizing may be a better choice for highly loaded coarse components [1].

Nitriding sometimes results in higher costs primarily because of cycle times and batch processing considerations. However, the cost increase typically corresponds to better properties. Another driver of cost is the cost of the base material. Nitrided steels tend to be produced from high alloy steels, which are usually more expensive [2].

In some cases, the carburizing process may prove more expensive, but the price of the base material (likely high alloy) must also be factored in [1][2].

[1]-https://blog.metlabheattreat.com/posts/nitriding-and-carburizing/#:~:text=The%20main%20difference%20is%20that,in%20carburizing%2C%20carbon%20is%20used.&text=Ion%20nitriding%2C%20on%20the%20other,is%20a%20more%20restrictive%20process.

[2]-https://www.eurotherm.com/en/heat-treatment-articles-en/what-is-the-cost-difference-between-carburizing-and-nitriding/#:~:text=For%20Carburized%20steels%20you%20would,processing%20and%20long%20cycle%20times.

See lessHow does a vacuum furnace roughing pump work?

The roughing pump is the component that primes the other pumps in series on the vacuum line, evacuating the system until a pressure level is reached at which a booster pump (known as a lobe-type roots pump) can be activated, followed by other types of diffusion, turbo molecular, cryogenic, ionic andRead more

The roughing pump is the component that primes the other pumps in series on the vacuum line, evacuating the system until a pressure level is reached at which a booster pump (known as a lobe-type roots pump) can be activated, followed by other types of diffusion, turbo molecular, cryogenic, ionic and other pumps that can be used when the pressure is reached.

Depending on the flow rate, the pumping system is proportioned in relation to system volume, pumping cycle speed, load degassing and contamination produced by the load (vapors, dust, binders, etc.) in the pump itself. It is for this reason that mechanical strength and wear influence the choice of pump type.

I highly recommend you to read an intersting article (splitted in two parts) about this topic:

Roughing pump in high-vacuum furnaces for beginners [1/2]

Roughing pump in high-vacuum furnaces for beginners [2/2]

See lessWhat is a 2-bar vacuum furnace vs. 6-bar vacuum furnace?

The term 2-bar is typically describing the quenching pressure capability of the furnace. A 2-bar operates (quenches) at 2-bar or 15 psig. A 6-bar would of course be operating at 6-bar when quenching. Typically quenching pressures are selectable and the ratings would be the maximum operating pressuRead more

The term 2-bar is typically describing the quenching pressure capability of the furnace. A 2-bar operates (quenches) at 2-bar or 15 psig. A 6-bar would of course be operating at 6-bar when quenching. Typically quenching pressures are selectable and the ratings would be the maximum operating pressures.

See lessCan a vacuum heat treat furnace be considered in a confined space?

Yes a vacuum furnace or any similar chamber can be considered a confined space. A confined space is any space with limited entry or egress. The primary concern in a vacuum furnace (confined space) is limited air flow or available oxygen to breathe. With vacuum furnaces we also have to consider theRead more

Yes a vacuum furnace or any similar chamber can be considered a confined space. A confined space is any space with limited entry or egress. The primary concern in a vacuum furnace (confined space) is limited air flow or available oxygen to breathe. With vacuum furnaces we also have to consider the fact that process gasses are also connected to the furnace or vessel. These gasses can also displace oxygen when used during back-fill or if leaking.

See less